Project Description

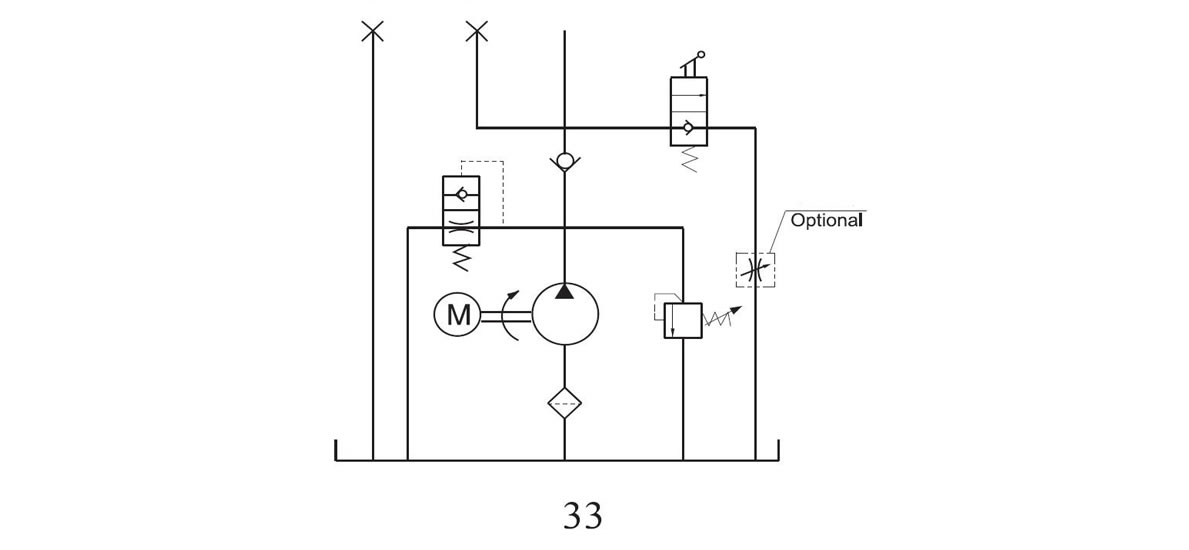

The car lift power unit, equipped with a 230V/AC/1.1KW motor, a 2537.5/2900PSI system pressure ,is widely used in auto hoist. The flow of the power unit is 0.59 to 1.09 GPM and it also has the cartridge valve. The oil reservoir is steel or plastic and its capacity is 1.58 to 3.70 gal, and the port is G1/4 or M14 x1.5 P1/P2.

This power unit is solely designed for car lift through motor power up, gravity down with vehicle weight. As we can offer different motors, Auto Hoist Power Units can be applied to different voltages and frequency. The lowering movement is controlled by the manual cartridge valve. The power unit is also applied to different kinds of hydraulic car lift and car scissors lift.

- Due to various types of hydraulic system failure occur more than 80% of the problems are caused by hydraulic oil, so the correct use of hydraulic oil to ensure the system’s reliability is very important.The oil viscosity should be 22-46mm2/s in accordance with ISO3448 viscosity classification.The hydraulic oil should be filtered by a 10-30um filter before put into use.N46 hydraulic oil is recommended.

- Clean all the hydraulic parts concerned before mounting mini hydraulic power pack.Check the oil level in the tank after the initial running of small hydraulic power unit.

- Oil changing is required after the initial 100 operation hours, afterwards once every 3000 hours.We are at your disposal to offer you the power unites with your favorite power,flow,pressure as well as the tank capacity.

- The electric hydraulic pump should be vertical installation.

- The AC motor of electric hydraulic pump is of s3 duty,which can only work intermittently and repeatedly, i.e., 1 minute on and 9 minutes off.

- To achieve thermal equilibrium of the electric motor, we have to assure that the ratio between interval time and operation time of mini hydraulic power pack is 1:9.

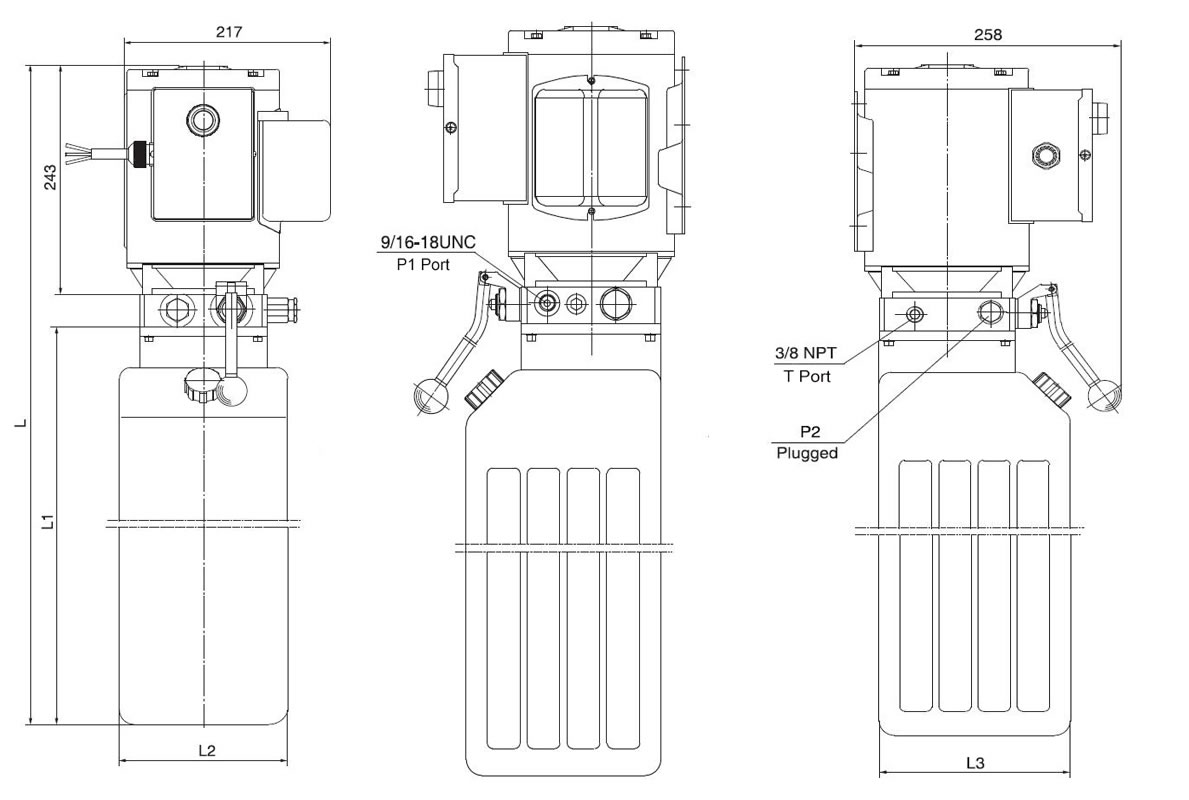

| Model | Volt engine | Power rating | Displacement | System Pressure | Rated Speed | Tank Capacity | Dimension(mm) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| L1 | L2 | L3 | The | |||||||

| HPP 1F0.86A11502V | 115V 60Hz | 1.1kW | 0.8mL/r | 20MPa | 3450RPM | 6L | 335 | 180 | 180 | 611 |

| HPP 1F0.88A11502V | 8L | 440 | 716 | |||||||

| HPP-1E1.26A11502V | 1.2mL/r | 17.5MPa | 6L | 335 | 611 | |||||

| HPP-1E1.28A11502V | 8L | 440 | 716 | |||||||

| HPP-1F0.86A115 / 23002V | 115/230V 50/60Hz | 0.8mL/r | 20MPa | 2830/3450RPM | 6L | 335 | 611 | |||

| HPP-1F0.88A115 / 23002V | 8L | 440 | 716 | |||||||

| HPP-1E1.26A115 / 23002V | 1.2mL/r | 17.5MPa | 6L | 335 | 611 | |||||

| HPP-1E1.28A115 / 23002V | 8L | 440 | 716 | |||||||

| Hpp-1F2.112A208 / 24004V | 208-240V | 2.2kW | 2.1mL/r | 20MPa | 2830/3450RPM | 12L | 540 | 165 | 185 | 816 |

| Hpp-1F2.114A208 / 24004V | 50 / 60Hz | 14L | 600 | 175 | 185 | 876 | ||||

| Hpp-1F2.112A230 / 46004V | 230 / 460V | 3450RPM | 12L | 540 | 165 | 185 | 816 | |||

| Hpp-1F2.114A230 / 46004V | 60hz | 14L | 600 | 175 | 185 | 876 | ||||

| HPP 1F2.112A3804V | 190/208/240/380/460V 50 / 60Hz | 2830/3450RPM | 12L | 540 | 165 | 185 | 816 | |||

| HPP 1F2.514A3804V | 2.5mL/r | 14L | 600 | 175 | 185 | 876 | ||||

| HPP-1E4.212A3804V | 4.2mL/r | 17.5MPa | 1450/1725RPM | 12L | 540 | 165 | 185 | 816 | ||

| HPP-1E4.214A3804V | 14L | 600 | 175 | 185 | 876 | |||||