Project Description

Description

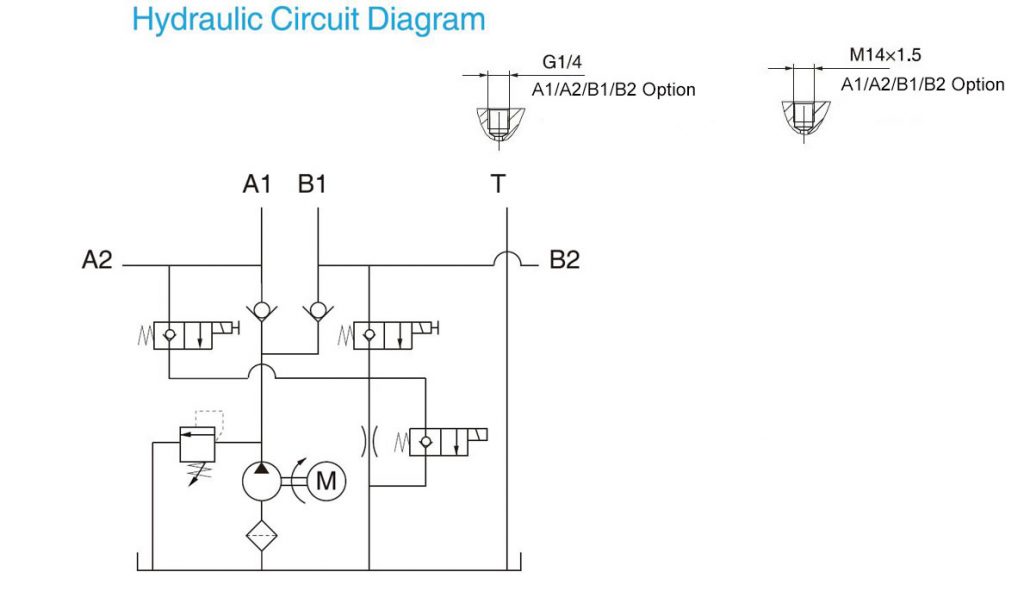

his power unit is widely used in hydraulic scissor lift. It is equipped with a 380V AC 2.2KW motor and the 24V DC cartridge valve. There are a steel oil reservoir with the capacity of 3.96 to 6.6 gal and a G1/4 or M14 x1.5 P1/P2/P3 oil port. The system pressure is 3335 to 3625 PSI and it flows 1.58 to 2.03 gal oil per minute.

This power unit features typical power up, gravity down with machine weight function. The lowering movement is controlled by the solenoid valve while the lower speed is controlled by throttle valve.

Cartridge solenoid valve with manual override function is available on request.

AC motors with CSA or UL certification are available upon request.

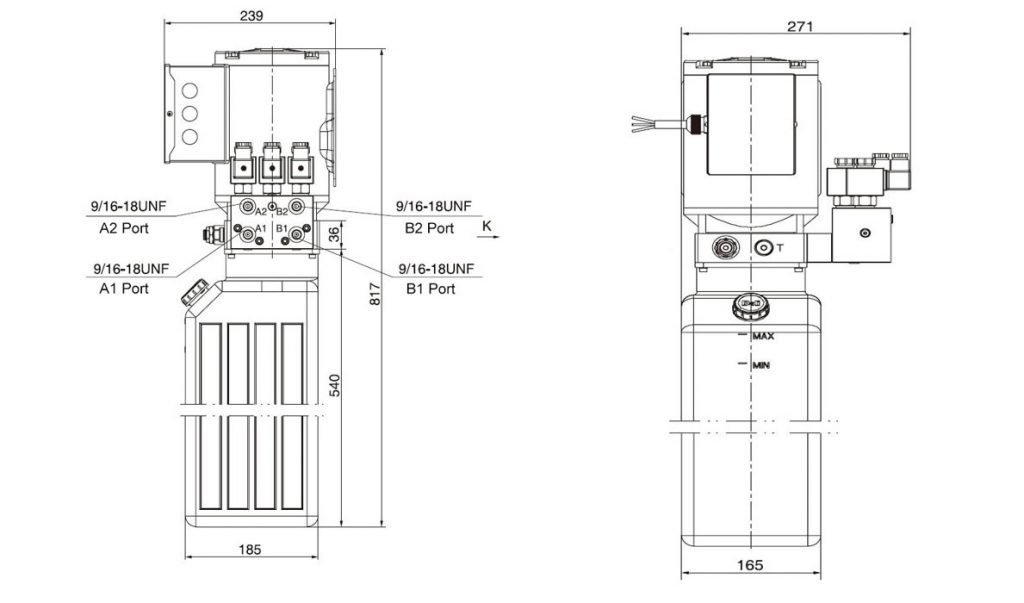

Drawing

Precautions

- Due to various types of hydraulic system failure occur more than 80% of the problems are caused by hydraulic oil, so the correct use of hydraulic oil to ensure the system’s reliability is very important.The oil viscosity should be 22-46mm2/s in accordance with ISO3448 viscosity classification.The hydraulic oil should be filtered by a 10-30um filter before put into use.N46 hydraulic oil is recommended.

- Clean all the hydraulic parts concerned before mounting mini hydraulic power pack.Check the oil level in the tank after the initial running of small hydraulic power unit.

- Oil changing is required after the initial 100 operation hours, afterwards once every 3000 hours.We are at your disposal to offer you the power unites with your favorite power,flow,pressure as well as the tank capacity.

- The electric hydraulic pump should be horizontal installation.

- The electric hydraulic pump is of S3 duty,i.e., non-continuous operation,30 seconds on and 270 seconds off.

- To achieve thermal equilibrium of the electric motor, we have to assure that the ratio between interval time and operation time of mini hydraulic power pack is 1:9.

- Mechanical locks are needed on both platforms to use this product.

| Model | Volt engine | Motor Power | Rated Speed | Displacement | Pressure | Tank | Valve Volt | Dimension(mm) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L1 | L2 | L3 | L4 | L5 | L6 | ||||||||

| HPP-2F2.115A380424V | 380 volt AC | 2.2kW | 2850RPM | 2.1mL/r | 23MPa | 15L | 24 volt DC | 516 | 240 | 260 | 340 | 180 | 320 |

| HPP-2F2.120A380424V | 20L | 586 | 310 | 260 | 340 | 180 | 320 | ||||||

| HPP-2F2.125A220424V | 220 volt AC | 25L | 586 | 310 | 290 | 360 | 210 | 340 | |||||

| HPP-2G2.515A220424V | 3KW | 2.5mL/r | 25MPa | 15L | 516 | 240 | 260 | 340 | 180 | 320 | |||

| HPP-2G2.520A380524V | 380 volt AC | 20L | 586 | 310 | 260 | 340 | 180 | 320 | |||||

| HPP-2F2.715A380524V | 2.7mL/r | 23MPa | 15L | 586 | 310 | 290 | 360 | 210 | 340 | ||||